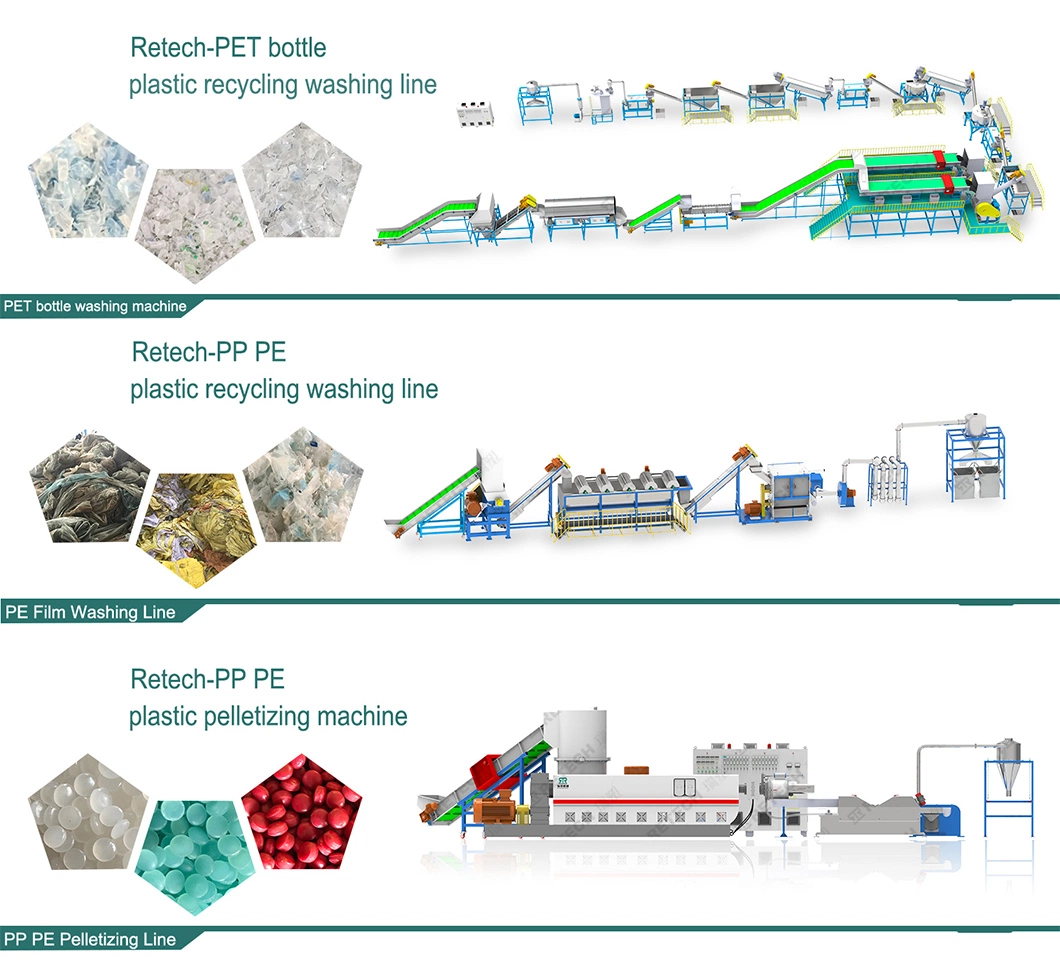

1000kg/Hr Complete PP PE Film Crushing Washing Squeezing and Pelletizing Line Recycling Solution

Basic Info.

| Model NO. | RTWWT |

| Plastic Type | PE HDPE LDPE LLDPE PP BOPP Film |

| Screw | Crusher&Shredder |

| Automation | Automation |

| Computerized | Customized |

| Certification | ISO9001:2008, CE |

| Material of Recycling Machines | Stainless Steel |

| Electric Grid | 3p 220~440V 50 or 60Hz |

| After-Sale Service | Eers Available to Service Machinery Overseas |

| Color | Could Be Customized |

| Transport Package | Wrap Film |

| Specification | TSWL300~3000 |

| Trademark | RETECH |

| Origin | China |

| HS Code | 8477800000 |

| Production Capacity | 300~3000kg/H |

Packaging & Delivery

Package Size 4200.00cm * 600.00cm * 500.00cm Package Gross Weight 36000.000kgProduct Description

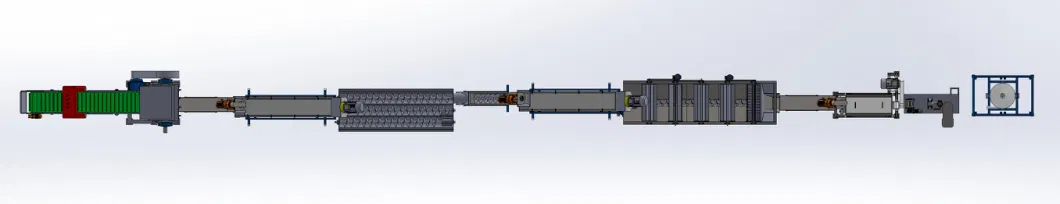

1000Kg/Hr Complete PP PE Film Crushing Washing Squeezing and Pelletizing Line Recycling Solution

Application Areas:PP PE HDPE LDPE Film Washing Recycling Machine of Wanrooetech is capable of processing a wide range of hard and soft plastic waste, for example, agricultural films, greenhouse films, package films,PE waste film,PP waste film,PVC waste film,industrial film,printed film and etc.Description :PP PE plastic washing recycling machine is widely used to washing recycling the used PP/PE plastic soft plastic. Such like shopping bags, packing films, garbage bags, woven bags, non-woven bags and films. This recycling machine can crushing washing and drying the dirty soft plastic into clean film flakes.After plastic film/bag flakes cleaned, you can make them into pellets/granules with next process, which called plastic pelletizing machine.This production line is high automatic operating and low consume, can save labor, save power and save water, easy to maintenance.With advanced design, concepts and technologies to suit different status of waste plastic bags/films. This PP PE plastic recycling machine could layout as "L", "S" or "U" shape according different workshop.

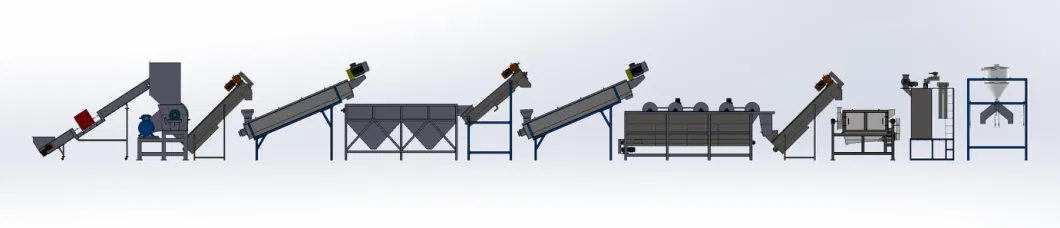

Process Flow of PP PE film washing line:

| NO | Process | Machine | Description |

| 1 | Send the film and bags to the wet crusher machine | Conveyor with Metal Detector(Optional) | It separates impurities such as metals in the films and bags,Send the materials to the wet crusher machine |

| 2 | Cuts the films and bags into small pieces size | Wet Crusher Machine | A wet crusher cuts the PP / PE film into small pieces approximately 10-20mm in size and moving onto the next piece of equipment. |

| 3 | Send the films and bags to the Floating Washing machine | Screw Feeder | Put the films and bags into the Hot washer to clean |

| 4 | The first time Floating wash the bags and films | Floating Washing Tank | As the PP / PE films enters the friction washer, the plastic film rubs against each other at high speeds getting rid of hard to remove contamination. |

| 5 | Feeding bags and film scraps to friction washer | Screw Feeder | Put the films and bags into the High-speed Friction Washer to clean |

| 6 | Separate the contamination from film and bags | High Speed Friction Washing Machine | After crushing material from enters the mouth, through the high speed on the axis of the blade flap and spray water to the common function of good cleaning effect. |

| 7 | The second time Floating wash the bags and films | Floating Washing Tank | It used in cleaning film and bags,make the film cleaner. |

| 8 | Dry the film and bags | Horizontal Dewatering Machine | The dewatering machine uses centrifugal force to spin water moisture off the films and bags. |

| 9 | Hot air to dry the films and bags | Pipeline Dryer | Using the hot air to take the humidity away from the clean material. |

| 10 | Storage dry pieces of films and bags | Storage silo | A storage tank for the clean, dry pieces of PP PE films and bags. |

| 11 | make film and bags into granules(Optional) | Pelletizer / Extruder | We offers both single-screw extruders and twin-screw extruders. Based on your requirements, we offer both one-stage and double-stage pelletizing setups where granules can be formed using a granulator or water-ring cutting. |

Features :To crushing washing recycling the used, dirty waste PP PE films/bags, protect the environment, Avoid white pollution.This recycling line is composed of crusher, cold & hot washing system, dewatering, drying, packing system, etc.This PP PE waste plastic crushing, recycling and washing recycling machine line can easily wash and recycle waste PP PE films/bags. Waste and dirty PP PE films/bags can be processed step by step, by this recycling machine. It is special for washing PP PE films/bags. We can help to attach equipment at the end of the washing recycling line so that the completely dry flakes can be collected and packed directly after been washed.The whole production line can designed based on how dirty the PP PE films/bags are, and make sure of the quality of the final products.

Product Parameters| Model | Capacity | Power | Water | Labor |

| RT-500 | 500kg/hr | 125kw/h | 4-5t/h | 1-2 |

| RT-1000 | 1000kg/hr | 215kw/h | 6-8t/h | 2-3 |

| RT-2000 | 2000kg/hr | 280kw/h | 8-10t/h | 2-3 |